On July 30th, in a virtual press conference, the Guatemalan Sugar Industry presented the prototype of the first mechanical respirator designed and manufactured in Central America, which has the capacity to assume up to 100% of respiration or provide partial assistance to a patient with lung deficiency.

Faced with the health emergency caused by the Coronavirus COVID-19 pandemic, the Guatemalan Sugar Industry, in addition to contributing with donations to the authorities, has promoted and supported projects focused on finding solutions to face this critical situation.

The Guatemalan Sugar Association – ASAZGUA – also announced the donation of 35 mechanical respirators to the Ministry of Public Health and Social Assistance, which will be financed by the Guatemalan sugar mills to save the lives of COVID-19 patients and when the pandemic ends, will be for use of future patients. By august those respirators will be at the Guatemalan hospitals.

Design and development process

The impact of COVID-19 in Guatemala, as in other countries, has caused a shortage of supplies and of medical equipment for hospital care. For this reason, the project for the development of the first mechanical respirator created in Guatemala was born, led by Engineer Edwin Delgado, Automation Superintendent of La Union Sugar Mill, who has 25 years working in the company.

Delgado, along with other experts, decided to take on the challenge of creating respirators to save Guatemalan lives. In March, with the approval and support of the managers of La Union Sugar Mill, the project began, which consisted on the design, development and creation of the first mechanical respirator for intensive care produced in Guatemala, to be called: Joaquin 1.0.

For this task, a group of professionals from La Union and other sugar mills met and together created pieces, developed software, and developed electronic systems. Physicians and pulmonologists also participated in this process, who contributed their experience and knowledge in this type of equipment.

Meet Joaquin 1.0

Joaquin 1.0 is a sophisticated respirator with digital displays that will bring oxygen to the lungs of people who are fighting for their lives and has the ability to take up to 100% of their breath or provide partial assistance to the patient.

Joaquin 1.0 is a sophisticated respirator with digital displays that will bring oxygen to the lungs of people who are fighting for their lives and has the ability to take up to 100% of their breath or provide partial assistance to the patient.

This respirator is more efficient than the use of a mask or other devices, by exerting enough pressure to keep the lungs open, preventing their collapse, and thus improving the passage of oxygen to the blood. People affected by acute respiratory problems and now with COVID-19 need such devices for hours or days, and in some cases, their need can extend to weeks or even months.

These devices are shortage worldwide due to the COVID-19 pandemic, which is why the Joaquin 1.0 respirator will be vital to keep patients who cannot breathe on their own due to the serious damage the virus causes to the lungs alive.

The respirator has a computerized control system that is in charge of controlling all aspects of breathing, in addition, it has a screen to present the graphics to the doctors that allows them to determine the best treatment that the patient requires. Many of the internal systems are redundant, backed by critical measurements, which ensure the life of the patient.

Also, the system has self-diagnosis with which it self-evaluates guaranteeing its operation. It also has an alarm system whose parameters are established by the doctor, and the respirator is responsible for monitoring that the patient does not leave these parameters.

A mechanical respirator that was born

in the heart of the Guatemalan Sugar Industry

Joaquin 1.0 was born in the heart of the Guatemalan Sugar Industry, in the workshops of La Union Sugar Mill. The Guatemalan Sugar Association – ASAZGUA-, from the beginning has believed in this project, for this reason it financed the purchase of 89 valves made in Germany for the construction of the first respirators, which are the engine for the operation of said equipment.

Joaquin 1.0 was born in the heart of the Guatemalan Sugar Industry, in the workshops of La Union Sugar Mill. The Guatemalan Sugar Association – ASAZGUA-, from the beginning has believed in this project, for this reason it financed the purchase of 89 valves made in Germany for the construction of the first respirators, which are the engine for the operation of said equipment.

Álvaro Ruiz, General Manager of the La Union Sugar Mill and Vice President of the Guatemalan Sugar Association -ASAZGUA- stated: “We are committed to Guatemala and therefore we do not hesitate to support this initiative. We have given Eng. Delgado the support, time, human resources, equipment and supplies to facilitate the process. We are very proud of what we are achieving.”

The respirator has already been tested with certified lungs, it is in the third phase, controlled trials with patients are expected next week. The joint effort of sugar mills, the Technical Institute for Training and Productivity –Intecap- and the company Fogel will be used in the production of these equipment.

“For me it is a personal satisfaction because the objective is being achieved, after the effort of several months of hard work in research and development. I am grateful to all the people who have supported with good disposition and in a disinterested way, concerned about the common good, giving life expectancy”, said Delgado. Regarding the name of the fan, the expert said: “It has been named in this way in honor and memory of my little angel Joaquincito“.

The Guatemalan Sugar Industry

maintains its commitment to Guatemala

The president of the Guatemalan Sugar Association -ASAZGUA-, Alfredo Vila, announced the donation of 35 mechanical respirators to the Ministry of Public Health and Social Assistance, which will be financed by the Guatemalan sugar mills to save the lives of COVID-19 patients and when the pandemic ends, they will remain for use by future patients.

“We support this effort because we believe in the capacity of our people and because it is part of our commitment to the well-being of Guatemalan families, to contribute to the efforts of helping people in these difficult times”, Vila said.

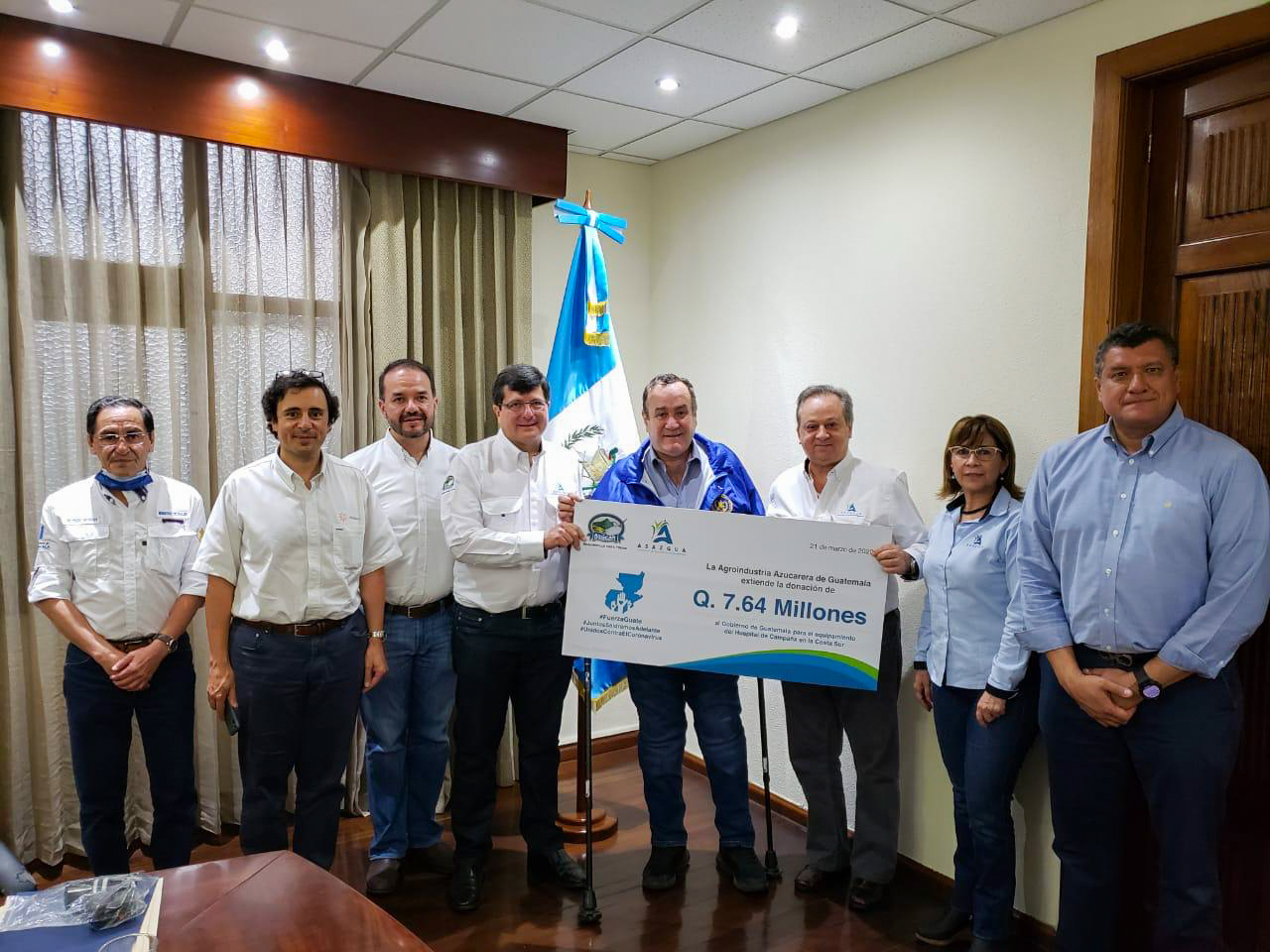

During the emergency by COVID-19, the Guatemalan Sugar Industry has made a series of contributions to the authorities, focused on confronting the situation, among them the donation of Q7.64 million for the equipment of the Campaign Hospital at the South of Guatemala, the usufruct of the land was also granted for the installation of said hospital. Likewise, more than 110 thousand pounds of sugar were donated for the “Saldremos Adelante” kit, which was delivered to 200 thousand families in vulnerable situations.

Press contact: ldiaz@azucar.com.gt